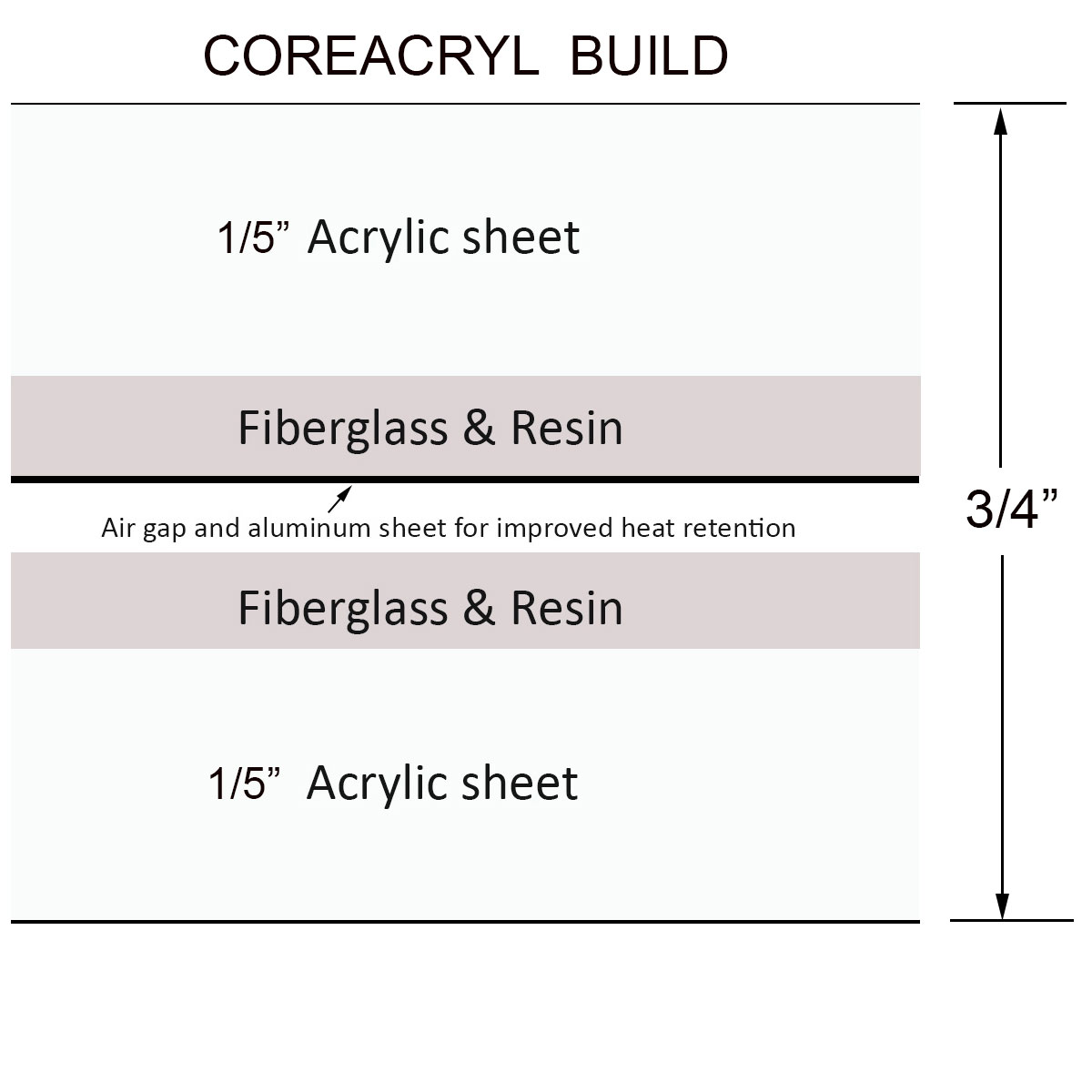

Hotel Collection & LUXWIDE Tub Construction using CoreAcryl

Our Hotel Collection range of tubs is built as shown in the above drawing. All tubs are built using CoreAcryl. The inner shell starts off as 3/16" pure high gloss acrylic sheet and is molded into the inner shell shape. Added to the inner shell are three layers of fiberglass with resin. A final aluminum heat shield layer is added to the inner shell. The outer shell process is the same, excluding the aluminum foil barrier. Resin mixed with powdered stone is then poured over the inner shell and the outer shell is pressure joined to the inner shell. We take great care to leave a narrow air gap as this allows the aluminum barrier to work correctly and avoid heat loss from the tub. This produces a solid, strong and relatively light weight body with a minimum wall thickness of 3/4". Extra reinforcing makes the tub floor over 1" thick. Unlike many other manufacturers, all of our tubs have slip resistant floors and are cUPC approved and listed.

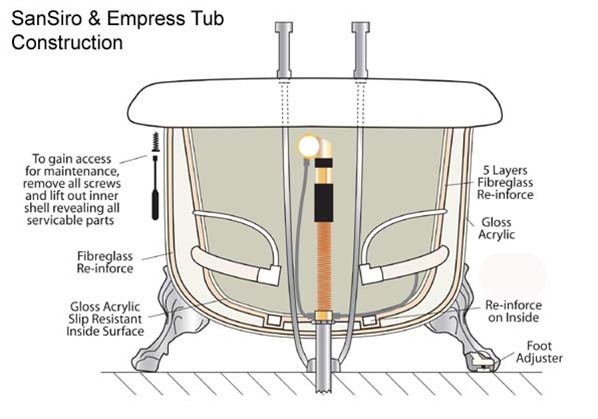

SanSiro and Empress Tub Construction

The picture above shows the construction of SanSiro and Empress tubs.

Feet Manufacture and Test Load

All of our tub feet are heavy cast metal and are coated and baked where necessary to produce a permanent high quality finish. All of our white feet are enamel baked.

Each tub style is tested to 1100 lbs, far exceeding the industry sttandard.